In recent years, the business landscape has witnessed a transformative surge in the adoption of 3D printing technology. Once considered a niche tool for prototyping, 3D printing in Perth has evolved into a mainstream force driving innovation across diverse industries.

One of the primary reasons for the growing popularity of 3D printing in business is its potential for cost savings. Traditional manufacturing processes often involve high upfront tooling costs and are less economical for small-batch or customized production runs. 3D printing eliminates the need for expensive moulds and tooling, allowing for more cost-effective production, especially for prototypes and limited production runs.

Aside from that, here are the factors contributing to the rising popularity of 3D printing in the business sector and the myriad ways it is reshaping the way companies design, manufacture, and bring products to market.

Rapid Prototyping

3D printing accelerates the product development cycle through rapid prototyping. Businesses can quickly transform digital designs into physical prototypes with the help of CNC routing services in Perth, enabling designers and engineers to iterate and refine concepts at a much faster pace. This speed to market gives companies a competitive edge by reducing development times and allowing for more efficient testing and refinement.

Customization and Personalization

The demand for personalized and customized products has surged in recent years. 3D printing facilitates the creation of unique, tailor-made items, from personalized medical implants to customized consumer goods. Businesses can respond to individual customer preferences, offering a level of customization that was once challenging to achieve through traditional manufacturing methods.

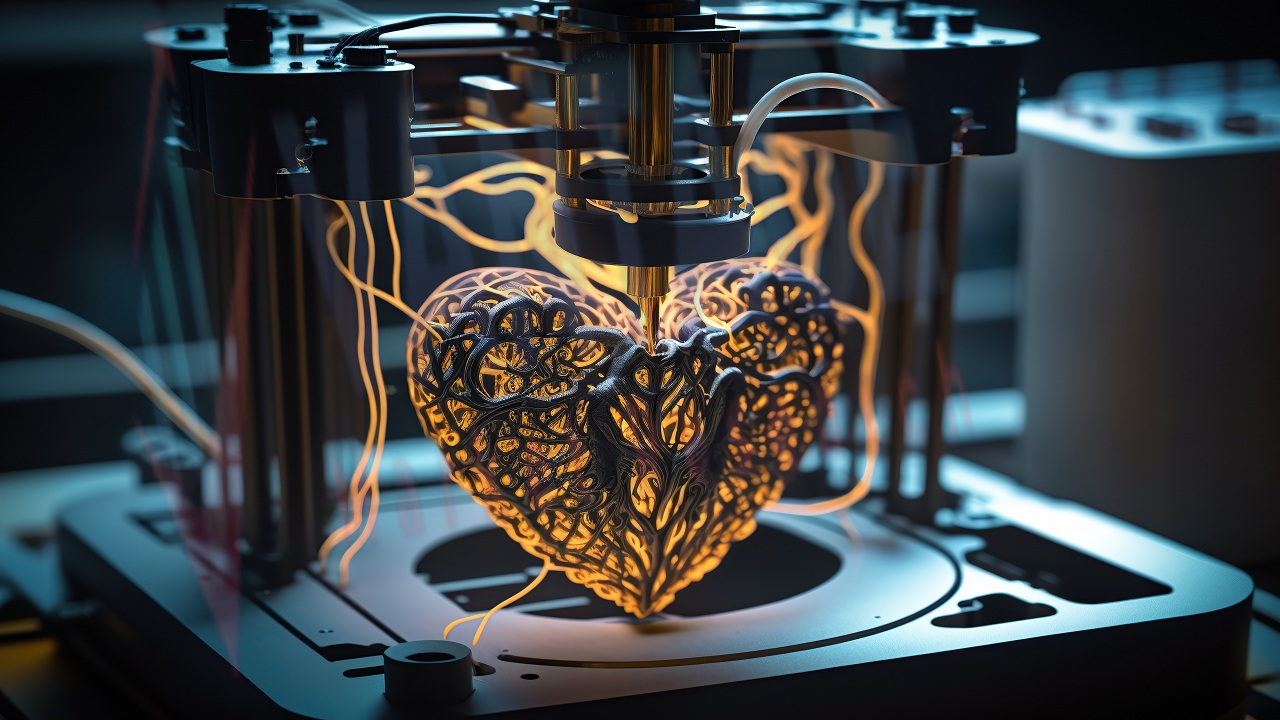

Complex Geometries and Intricate Designs

Traditional manufacturing processes often need help in producing complex geometries and intricate designs. 3D printing, however, excels in creating complicated structures and complex shapes with precision. This capability is particularly valuable in industries such as aerospace, healthcare, and automotive, where lightweight and intricately designed components are essential.

Supply Chain Resilience

The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting businesses to reevaluate their manufacturing strategies. 3D printing offers a decentralized approach to production, allowing companies to manufacture products on-site or near-site. This not only reduces dependence on distant suppliers but also enhances supply chain resilience by minimizing disruptions.

The escalating popularity of 3D printing in the business industry can be attributed to its transformative impact on manufacturing processes, cost efficiency, and the ability to bring innovative ideas to life rapidly. As businesses increasingly recognize the value of this technology in fostering creativity, customization, and supply chain resilience, 3D printing by Artcom Fabrication is poised to play an integral role in shaping the future of how products are conceived, designed, and produced in the dynamic landscape of the business world.

Comments